Med den bedste robotteknologi vil vi også gerne levere til dig.

Reliable solution for multiple variants

Today automating machine tools using robots is standard practice, but when it comes to handling a wide range of models it can quickly become a challenge. An experienced system integrator is able to offer optimal solutions even for difficult cases, as demonstrated by the revolutionary automation of the machining centre of a major electronics manufacturer.

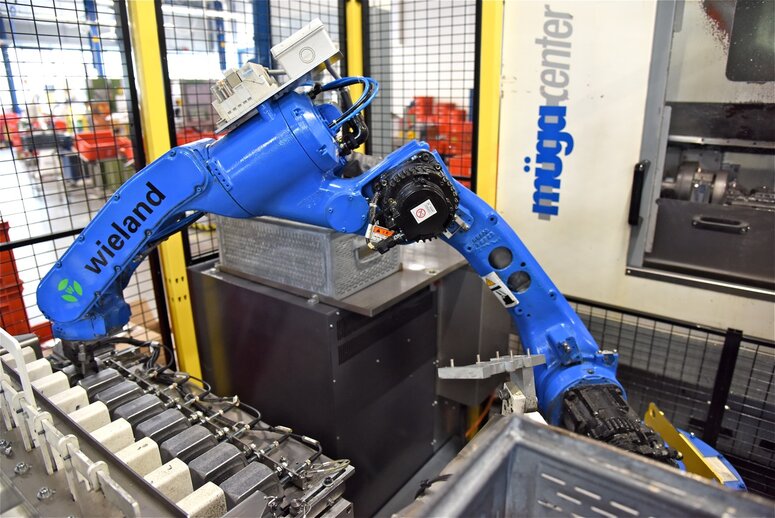

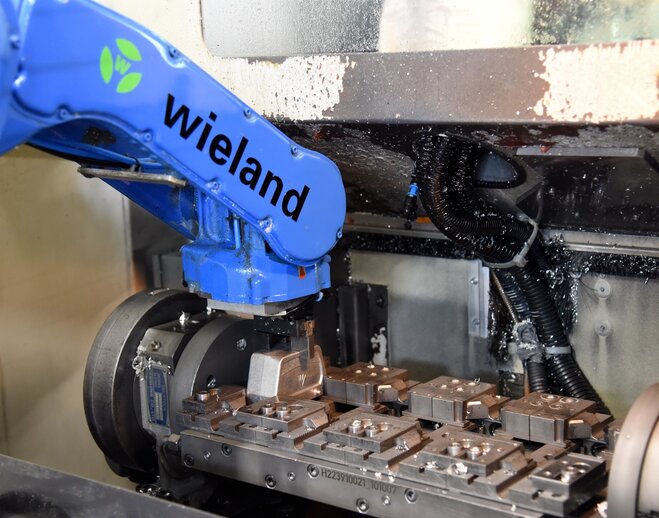

Wieland Electric GmbH is one of the pioneers in electrical connectivity solutions and, in over 100 years of existence, has become an international group with a global workforce of over 2,200 people on all five continents. The company manufactures the enclosures for the Revos industrial connector series in the Franconian city of Bamberg. A Müga S500 machining centre drills holes and threads in the upper and lower sections of the housing.

The challenge

In the past, the machine tool was loaded and unloaded manually, engaging the employees in simple and monotonous tasks necessary for higher level activities, and penalizing productivity.

In order to remedy the situation, EGS Automatisierungstechnik had to develop a solution that could handle two complex factors: firstly, the large number of housing models and, secondly, the fact that the housing components are delivered messy in metal containers and leave the system as bulk material again.

The solution

Thanks to some modifications, the solution was found in SUMO Flexiplex, a loading system part of the EGS standard range of solutions that transports parts on multi-lane belts. Since all versions of the connector housing have a width between 42.5 and 43.5 millimeters, the lane width of the Flexiplex does not need to be adjusted when retooling. Variations in length, height or profile were not a problem. It was only necessary to install a clamping arm.

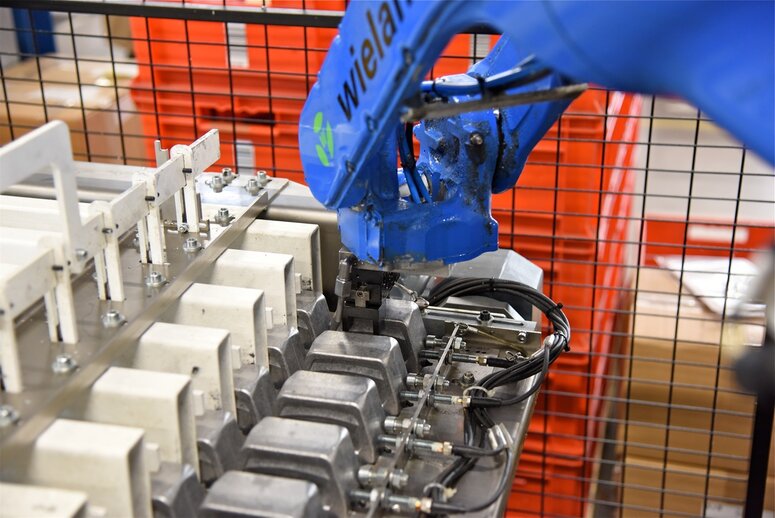

In contrast to the feeding system, choosing the right robot was easy. EGS opted for a Motoman MH12 for all handling tasks within the cell. The correct positioning of the eight Flexiplex lanes at the housings remains the task of the operator, as well as the positioning of the empty metal bins for the collection of machined parts.

After starting the automatic machining, the feeding system feeds the parts into the working area of the robot. The entire range of parts is handled with a single gripper, thanks to the uniform width. The MH12 robot collects the parts and inserts them into the machine's clamping system. Once all the housings are loaded, the robot applies tension to the empty spaces and provides the start signal to the machine, which then rotates the loaded side of its rotary table into the machining area and transfers the finished parts to the loading and unloading area.

The results

The system has set a new benchmark in terms of cycle times, currently four parts per minute. The autonomy can be up to several hours depending on the component variant and the availability of parts to be processed and unloading containers.

The use of a robotic solution has made it possible to safeguard the well-being of employees, preventing them from being exposed to lubricants or splinters.

The Motoman MH12 robot, thanks to its excellent workspace management, has been positioned at a distance from the tool machine so that it can also be operated manually - if necessary, for example for small series.