Med den bedste robotteknologi vil vi også gerne levere til dig.

Bilindustrien

Yaskawa Denmark LØSNINGER Industries Bilindustrien

Overview

Både bilproducenter og deres leverandører sætter deres lid til Motoman robotter i alle faser af produktionsprocessen.

MOTOMAN robots and robotic systems for manufacturing electric vehicles

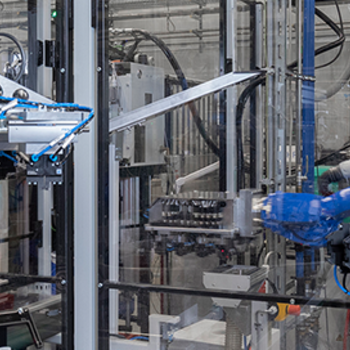

The growing popularity of electric cars has translated into increased demand for batteries dedicated to this type of vehicles. To meet this demand, battery manufacturers are increasingly implementing robotic systems that, by providing fast, reliable component assembly, make it easier to meet the growing market demand.

Robots are now playing an increasingly important role in the production of lithium-ion batteries (LIBs), for example, in the cell assembly and component picking processes, as well as in packaging and in-vehicle assembly - all in accordance with the recommended joining and assembly technology.

Handling Large and Heavy Tray Assemblies

For the building up of most tray assemblies, robotic automation really is the only logical solution – as tray assemblies are generally large and heavy. Certain vehicle battery trays can be as large as six feet by eight feet and weigh almost 300 lbs. The weight and size of these assemblies – as well as the necessary placement of the battery – make robot utilization a smart choice.

More and more, Motoman robots are involved in Battery swapping solutions in public transport.

Production and Assembly of Battery Trays

In the production of aluminium battery trays, we see thermal joining techniques like arc welding, laser welding and friction stir welding.

Dispensing/spraying Adhesives with Motoman Robots

Many of the applications previously listed present risk factors and can be harmful to human workers. From heavy and repetitive lifting of parts, to the inhalation of toxic fumes during the adhesive dispensing process, the use of robots for these potentially dangerous activities is advised.

See more in our "Dispensing" Application Section.

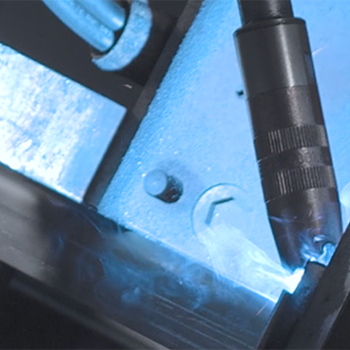

Thermal Drilling (FlowDrill) with Motoman Robots

FlowDrill is a process forming a hole and then forming a thread. This can be done by a FlowDrill Tool, or by a screw fastener providing the special FlowDrill geometry required to warm up the metal.

The FlowDril process requires a very high contact pressure in the first phase, where the tip of the tool / fastener is forming the hole. The robot requires a good stiffness and rigidity to withstand this force, and no backlash and rigity to keep his position for a stable quality of the FlowDril Process. For this job, the Motoman GP250 or GP280 are ideal.

See more in our "Mechanical Joining" section.

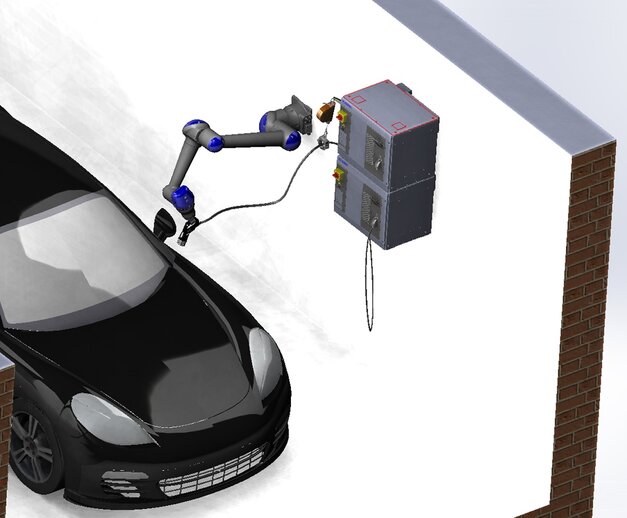

Charging Infrastructure with Motoman Robots

Automatic charging of Robots - a dream on int's way to realisation, because of upcoming high edge vision technology, connectivity, autonomous software functions of vehicles - and collaborative Motoman HC Series robots !

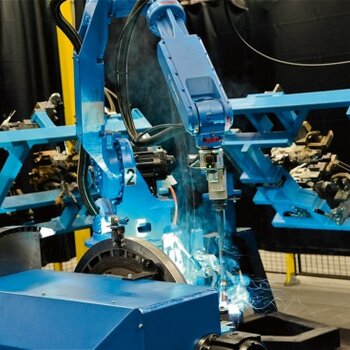

Motoman Robots in the Automotive Body Shop (BIW)

Automotive Body-in-White (BIW) Shops hold the largest installed base of robots in the world. Motoman Robots are involved in many advanced core technologies which are concentrated in a Body Shop - Spot welding, Laser Welding, Remote Laser Welding, Arc Welding, Glueing, Fastening of all kinds, Roller Hemming, Sealing, Inline-Measurement, Handling and many more.

Motoman Robots in the Automotive Press Shop

In Automotive OEM press shops, body panels are stamped and cut in stages from the raw material to ready shaped floors, body sides, pillars, hoods and flaps, doors. Motoman Robots are feeding those presses in and out, in multi-stage press lines they are transporting panels between presses.

Motoman Robots in the Automotive Paint Shop

Motoman Robots are actors in the Automotive Paint Shop - Car body / Door/ Hoods / Flaps / Bumpers interior and exterior painting, underbody and interoir sealing and applying sound deadener.

Motoman Robots in Automotive Final Assembly

The automation rate in Automotive final assembly in Automotive is still low. Robotic Applications have been established in caged-in stations for handling material, roof assembly, wheel assembly, carpets/mats and dashboard assembly, battery handling, inspection and several screwdriving applications. Mobile robots are on the rise to do Kanban refills or moving defective parts to a central repair station. Collaborative Robots will be a valuable contribution to automate final assembly in the following years.

Motoman Robots in Automotive Quality Control

Motoman Robots doing inspection tasks in quality gates.

Motoman Robots in Automotive Interior Manufacturing

Interior parts are highly customized today. They are just-in-time parts, delivered by Tier1s who need very flexible automation to address the changing designs and batch sized required by the automotive OEM.

Motoman Robots in Automotive Powertrain Part Manufacturing and Assembly

In the powertrains of today's cars, we still find a high majority of combustions engines, who have an established supply chain to manufacture the parts (CNC machining) and assemble the parts, both at the OEM and Tier1/2 Suppliers. Here we see a lot of Motoman Robots involved in CNC machine tending, assembly and quality inspection.

Motoman Robots in Automotive Exhaust Systems

Motoman is the market leader for Automotive Exhaust Production Cells and lines. A majority of the large Tier1s are trusting YASKAWAs long term experience in line building and process know-how. Motoman Arc Welding Robots are accompanied by a large portfolio of positioners, tracks and gantries, and specialized exhaust assembly machinery like muffler presses. See more in our "Arc Welding" section.

Motoman Robots in Automotive Seating

You will see Motoman Robots and Turnkey System at large Tier1 Seating suppliers throughout the world. YASKAWA's unique professional line building competence in Arc Welding, Laser Weding and Spot Welding appliciations as well as our expertise in production line engineering will convince you to have the right partner for your automation needs.

Motoman Robots in Automotive Intralogistics

Automotive Part Intralogistics is a challenge which is more and more automated with robots. See more in our "Logistics" section.

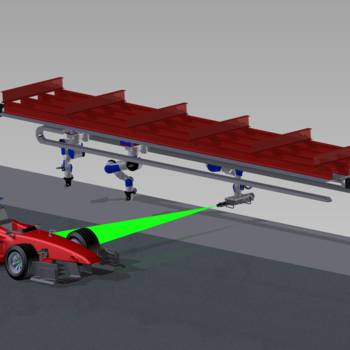

Offline Simulation and Programming Support for Motoman Robots

We are supporting the Automotive Offline Simulation world, e.g. RobCad or Process Simulate, and provide kinematic models and RCS modules. On cell level, we offer our own lean Engineering Tool MotoSim, capable to do cell layouts, reach and cycle time simulations and robot programming (OLP, Offline Robot Programming) with up-/download to the robot controller. Motosim supports all robot models, master/slave constellations, positioners, gantries, tracks from our portfolio, and in addition CAD model uploads with kinematisation.